Sustainable robotics: repairing soft robots with the 3D printer

Soft robots are difficult to repair or upgrade. With a process that uses support gel and a 3D printer, this is possible.

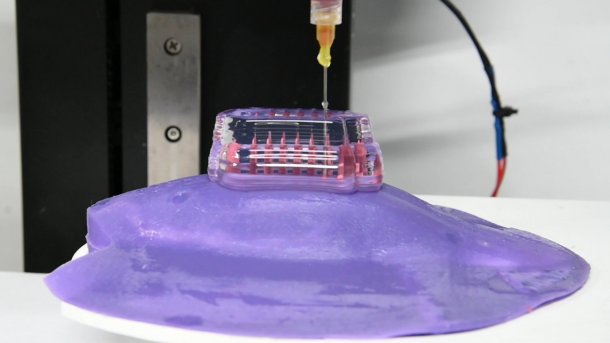

A 3D printer is used to apply support gel to a ray-shaped soft robot as a basis for repairs.

(Image: Elgar Kanhere u. a.)

Scientists at the Singapore University of Technology and Design have developed a method of repairing soft robots using a 3D printer and special support gels. According to the researchers, older versions of soft robots can also be upgraded and reused instead of being disposed of.

Soft robots are difficult to repair and upgrade. They usually consist of large soft molded parts or soft material in one piece. As a result, the robots cannot be repaired if they are damaged. It is also very difficult to modify such robots, for example to extend their range of functions, so they are disposed of and new versions are created from scratch.

Videos by heise

To avoid this, researchers at the Singapore University of Technology and Design have developed a new approach, which they describe in the study “Upgrading and extending the life cycle of soft robots with in situ free-form liquid three-dimensional printing”, published in Science Robotics.

Repairing and upgrading soft robots with 3D printing

The additive in-situ manufacturing process is based on 3D printing. Special support gels that retain their shape under gravity are printed onto areas of a soft robot that need to be improved. The 3D printer then prints the necessary repairs onto the surface covered by the gel. The gel acts as a stabilizer so that the newly printed parts can hold in place and harden. After curing, the gel is washed off with water. The newly printed components are then seamlessly integrated into the soft surface of the robot.

The researchers use special support gels for different surfaces and materials. The process can therefore be applied to various different robots and devices.

The scientists tested the process on a soft, ray-shaped robot. They retrofitted the robot with tactile sensors and a passive whisker array, as well as movable hooks. They repaired the soft surface of the robot, which had been damaged as a result, using the method described. The outdated robot could thus be modernized without having to completely rebuild it.

The researchers are convinced that the additive in-situ process can also be applied to electronic devices. Intelligent household appliances, smartphones and other devices could also be repaired using this method.

(olb)