Figure AI builds BotQ factory for mass production of humanoid robots

Figure AI wants to bring its humanoid robot Figure 03 to market quickly and is pushing for mass production. The BotQ factory was developed for this purpose.

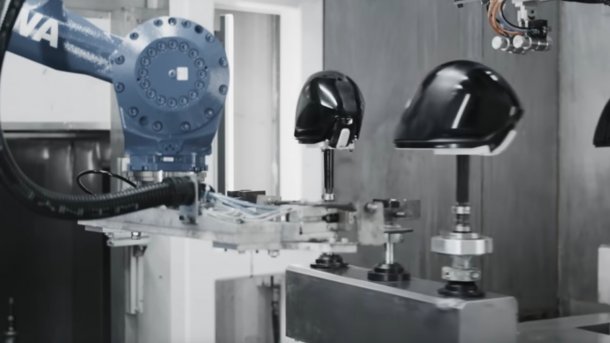

In Figure AI's BotQ factory, complete humanoid robots are to be manufactured in a largely automated process.

(Image: Figure AI (Screenshot))

The US robotics company Figure AI has revealed initial insights into an upcoming BotQ factory in which humanoid robots are to be built in large quantities. Initial tests of the production processes are already underway. Figure AI plans to produce around 12,000 robots a year in the BotQ. Initially, this will be the humanoid Figure 03, which has been optimized for mass production.

Figure AI wants to retain complete control over the production process of its humanoid Figure 03 robots. This will only be possible if the robots are produced in-house and not by contract manufacturers. The company wants to be able to better monitor and control the manufacturing process and quality.

Development and implementation of the manufacturing process

Figure AI has been working on the concept of an efficient and scalable manufacturing process for its robots for eight months. Before this could happen, however, the Figure 02 first had to be further developed to ensure simpler production, moving away from individual production and towards mass production. This includes, for example, simplifying and combining components into entire groups in order to be able to assemble the robot more quickly.

Empfohlener redaktioneller Inhalt

Mit Ihrer Zustimmung wird hier ein externes YouTube-Video (Google Ireland Limited) geladen.

Ich bin damit einverstanden, dass mir externe Inhalte angezeigt werden. Damit können personenbezogene Daten an Drittplattformen (Google Ireland Limited) übermittelt werden. Mehr dazu in unserer Datenschutzerklärung.

Individual parts are no longer CNC-milled, but manufactured using tool-based injection molding, die casting, metal injection molding and stamping processes. This reduces manufacturing time and production costs. One example: parts that took over a week to mill in a CNC machine are now produced in steel molds within 20 seconds. Although this initially entails high investment costs, it pays off in mass production, says Figure AI. This is because the robot must be designed in such a way that it is not too expensive and reaches a certain price point. Figure AI is not yet revealing what this will be.

What is certain, however, is which robot will be the first to roll off the production line in the BotQ factory: the Figure 03. Figure AI has redesigned the robot from the ground up for this purpose. The actuators, motors, sensors, batteries and electronics. The Figure 03 has already been manufactured from the optimized components using simpler processes.

However, it is not possible without external partners supplying parts. Figure AI has entered into initial partnerships with suppliers in order to establish a stable supply chain for the special components. The robotics company believes it is so well positioned that the production of 100,000 robots or 3 million actuators would be possible within the next four years.

Automation with humanoid robots too

Production engineers are now in the process of designing production lines and optimizing and testing processes. Part of the production process is automated, while another part is done manually. In particular, processes that can be carried out faster and more precisely by a robot than by a human are being automated. These include quality checks in the area of battery cells and the production of individual key components. Figure AI also intends to use its own humanoid robots in production for repetitive tasks. The company assumes that this could happen as early as 2025.

Videos by heise

Ultimately, robot production in the BotQ factory will be a combination of automation controlled by artificial intelligence and human supervision.

(olb)