US researchers create material for construction with a negative carbon footprint

Large quantities of carbon dioxide are released during the production of building materials. With a new process, they could even become a carbon dioxide sink.

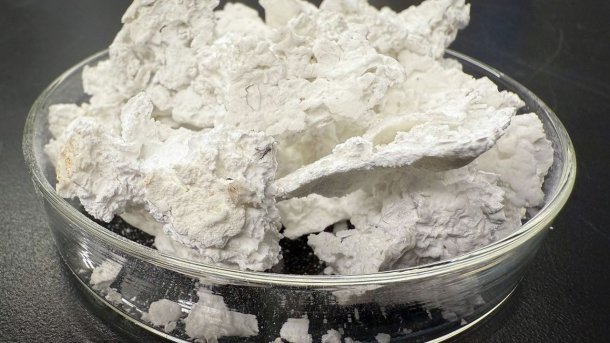

Minerals as a base material for various building materials

(Image: Northwestern University)

The production of building materials is one of the largest emitters of carbon dioxide. This is set to change: A team from the USA has developed a cement that is said to have a negative carbon footprint.

The team led by Alessandro Rotta Loria from Northwestern University in Evanston, Illinois, uses seawater, carbon dioxide and electricity to produce building materials – concrete, cement, plaster or paint.

"Cement, concrete, paint and plaster are typically made from calcium and magnesium-based minerals, often derived from aggregates – i.e. sand –," says Rotta Loria. "Currently, sand comes from mountains, riverbeds, beaches and the seabed."

Sand from seawater

Together with the building materials manufacturer Cemex, the team has developed an alternative approach to sand extraction, says the researcher: "Not by dredging, but by using electricity and carbon dioxide to produce sand-like materials in seawater." Seawater because it is more readily available than fresh water.

To do this, electrodes are suspended in seawater and a weak current is applied. This splits water molecules into hydrogen and hydroxide ions. At the same time, they released gaseous carbon dioxide into the seawater. This changed the chemical composition of the water and the concentration of hydrogen carbonate ions increased.

Finally, the hydroxide and hydrogen carbonate ions reacted with other ions dissolved in the seawater, such as calcium and magnesium. The solid minerals calcium carbonate and magnesium hydroxide flocculate.

Process similar to the formation of corals

This then becomes sand. Calcium carbonate acts directly as a carbon dioxide sink, magnesium hydroxide binds the carbon through further interactions with carbon dioxide. The process is similar to the way corals form their skeletons.

By changing parameters such as voltage and current, the amount and timing of the addition of carbon dioxide and the circulation of seawater in the reactor, the composition of the minerals could be altered. They became fluffier and more porous or denser and harder, but they always consisted mainly of calcium carbonate and/or magnesium hydroxide.

"We have shown that when creating these materials, we can completely control their properties, such as chemical composition, size, shape and porosity," says Rotta Loria. "This gives us some flexibility in developing materials that are suitable for different applications." They could be used as a substitute for sand or gravel in the production of building materials – These make up 60 to 70 percent of concrete, for example.

Carbon dioxide emitter cement industry

According to the World Economic Forum, the cement industry is the fourth largest emitter of carbon dioxide. It accounts for around 8 percent. "We could create a cycle in which we bind carbon dioxide directly at the source," says Rotta Loria. "And if the concrete and cement plants are located on the coast, we could use the sea right next to them to feed special reactors that use clean electricity to convert carbon dioxide into materials that can be used for countless applications in the construction industry."

Videos by heise

Another advantage: sand for building materials is scarce and is being mined at ever greater depths in rivers and oceans or dug deeper from the earth. This only damages the environment and drives up costs. Criminal organizations, also known as sand mafias, have even formed to extract sand illegally. Artificially created sand could provide a remedy here.

(wpl)