Waveguides explained: How the display in smart glasses and AR glasses works

Waveguides generate digital images directly in the field of vision and enable smart glasses such as the Meta Ray-Ban. We explain the technology behind them.

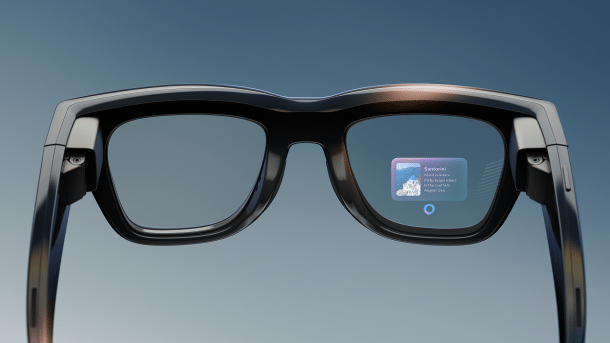

The Meta Ray-Ban Display uses a waveguide display in the right lens for image projection.

(Image: Meta)

Waveguides, as they are known in German, can be thought of as paths that guide light, radio waves or sound from one place to another. The waveguide displays in smart glasses and AR glasses are a special form of waveguide developed for the precise guidance of light. This is why they are also referred to as optical waveguides in this context.

Optical waveguides are a widely used form of waveguide: In the form of fibre optic networks, for example, they form the basis for the internet and modern telecommunications. While glass fibres are cable-like and flexible and transport modulated infrared light over long distances, the optical waveguides in smart glasses and AR glasses are flat and rigid and guide visible light over a few centimetres directly into the eye.

How waveguide displays work

A waveguide eyewear display essentially consists of two components: the light engine, which is usually located at the front of the frame near the hinge, and the waveguide itself, which forms the lens or part of it.

The light engine has two central functions: Firstly, it provides the light source and generates a tiny image using a microdisplay, utilising different technologies such as LCoS, Micro-OLED or MicroLED depending on the product. Secondly, it directs the light beams and guides them into the waveguide at the required angle.

The waveguide itself consists of a substrate with the highest possible refractive index. This is typically specially manufactured glass or plastic. The waveguide has three important tasks: It couples the light from the light engine, guides it along the lens to its destination and decouples it again so that it reaches the wearer's eye in a targeted manner.

(Image: Schott)

On its way through the waveguide, the light remains trapped in the substrate due to a physical phenomenon called total internal reflection and moves within it as if in a mirror corridor. Total internal reflection occurs when light from a medium with a higher refractive index (waveguide substrate) hits a medium with a lower refractive index (usually air or a surrounding carrier lens made of glass or plastic). Whether it remains in the substrate depends on the angle of incidence: if this exceeds the so-called critical angle, the light is completely reflected. The greater the difference between the refractive indices, the greater the angle range in which the light can be retained in the substrate. This improves the efficiency of the light guidance and the waveguides can be designed to be thinner and more compact.

Finally, when the light is decoupled, the originally tiny image of the light engine is fanned out by the waveguide, creating the impression of an image surface floating in space. This fills smaller or larger parts of the field of view.

Ultimately, a waveguide display has to do two things: it guides artificial light directly into the eye and thus into the field of vision, while at the same time allowing natural light to pass through its surface so that the surroundings remain visible. The combination of both light sources results in digital overlays that superimpose and expand the physical world.

(Image: Schott)

Transparency is a key characteristic: it distinguishes Waveguide displays from classic displays in mixed reality headsets such as the Meta Quest 3 or Apple Vision Pro. There, an LCD or OLED screen sits directly in front of the eyes, completely blocking the view of the outside world. The real environment is recorded by cameras and reproduced as a video image: a technology known as "passthrough", which differs fundamentally from the "see-through" of optical display systems such as waveguides. If a mixed reality headset switches off, you are in the dark. If, on the other hand, a waveguide display fails, the surroundings remain visible. However, the light transmission can vary from waveguide to waveguide.

Videos by heise

There are different waveguide displays

There are various types of waveguides, which differ primarily in the way they couple light in and out. The most common type are diffractive waveguides, which diffract the light from the light engine using nanostructures imprinted in the waveguide substrate ("diffraction" is the English word for diffraction). Diffractive waveguides are used in many well-known devices such as Hololens, Magic Leap, the current Snap Spectacles and Meta's Orion prototype.

Geometric reflective waveguides are another emerging type of waveguide display, the development of which is being driven by waveguide pioneer Lumus. This type of waveguide is used in the Meta Ray-Ban display. These waveguides bear their name because they are based on classic geometric light paths with mirrors and prisms, in contrast to diffractive waveguides, which direct the light by diffraction. Instead of nanostructures, layers of semi-transparent mirrors guide the light into the eye. "The image quality is defined by the geometric arrangement of these mirrors," explains Rüdiger Sprengard, Head of Augmented Reality at German speciality glass manufacturer and Lumus partner Schott, which manufactures waveguides of both types.

(Image: Lumus / Meta)

Both types of waveguide require different manufacturing processes, each with their own challenges that can affect the yield. With diffractive waveguides, structures in the nanometre range must be imprinted across lens-like surfaces with almost zero defects. Geometric reflective waveguides, on the other hand, require extremely precise coating and arrangement of semi-reflective surfaces on glass, whereby even the smallest deviations can cause differences in brightness or colour interference.

(Image: tobe)

For a long time, it was unclear whether geometric reflective waveguides could ever be produced in large quantities. Schott has now mastered series production. And according to Meta's Head of Technology Andrew Bosworth, it is Schott that manufactures the waveguides for the Meta Ray-Ban display in Malaysia.

Bending or reflecting light: Strengths and weaknesses

The advantages and disadvantages of the two types of waveguide can be clearly seen in Meta's eyewear models. A year ago, Meta presented the technically impressive AR glasses prototype Orion, which utilises diffractive waveguides. This was followed this month by the announcement of the market-ready Meta Ray-Ban Display smart glasses, which use a Geometric Reflective Waveguide instead. Has Meta changed the type of waveguide within a year? Not at all because the models belong to different product categories, each with their own requirements.

Orion is an attempt to develop fully-fledged AR glasses with the slimmest possible form factor: it offers a particularly wide field of vision for digital overlays, can capture the environment spatially and anchor digital objects in it. In addition to eye and hand tracking, they are also potentially capable of displaying 3D graphics instead of just image areas. However, it is likely to be a few years before Meta's AR vision reaches technological and commercial maturity.

(Image: Meta)

Meanwhile, Meta is pursuing a more modest goal with the Meta Ray-Ban Display: the Ray-Ban Meta brand smart glasses, which previously had no display, are being expanded to include a small display in the right eye that fulfils various functions. For example, it displays responses from the AI assistant Meta AI, shows messages from WhatsApp, Messenger and Instagram, serves as a viewfinder for photos and videos and supports users with visual navigation.

(Image: Meta)

One of the strengths of diffractive waveguides is that they enable a particularly wide field of vision, which is why Meta opted for this type of waveguide for Orion. The refractive index of the substrate plays a key role in diffractive waveguides: the higher it is, the wider the digital field of view can be. With a waveguide substrate made of silicon carbide instead of glass, Orion achieves an unusually wide field of view of 70 degrees for this form factor. This corresponds to a digital projection surface around 16 times larger than that of the Ray-Ban Meta Display. At the same time, silicon carbide reduces one of the biggest weaknesses of diffractive waveguides: wavelength-dependent light diffraction, which often causes colour distortions and rainbow effects. The catch: silicon carbide is so expensive to produce that commercialisation is currently out of the question.

As the Ray-Ban Meta Display is not designed for a large field of vision anyway, Meta opted for a Geometric Reflective Waveguide, which is cheaper to produce and offers advantages in other performance areas. This type of waveguide utilises semi-transparent mirrors that reflect the light almost loss-free and independent of the wavelength. As a result, the waveguide display achieves significantly higher image quality, brightness and efficiency than diffractive waveguides, enabling a smart glasses display that can be used for several hours and remains visible even outdoors in bright daylight.

(Image: Meta)

Another advantage of the Geometric Reflective Waveguide is that the display is barely visible to outsiders. Diffractive waveguides, on the other hand, often generate annoying reflections to the outside, which can impair eye contact. "The problem is that these waveguides are not directionally selective. They want to send just as much image to the outside world as into the eye. The mirrors [of the Geometric Reflective Waveguides], on the other hand, have very few reflections towards the world," says Sprengard, describing this circumstance as a "gift of nature".

For Sprengard, it remains to be seen which type of waveguide will ultimately prevail. What is certain, however, is that both technologies will continue to develop. Substrates with a higher refractive index and new, more precise embossing techniques from semiconductor production could reduce the weaknesses of diffractive waveguides. Geometric reflective waveguides will catch up in terms of field of view, as this is less dependent on the refractive index. Lumus has already announced that it will present a new waveguide design next year whose field of vision could compete with Orion. In addition to waveguides, work is also being carried out on more powerful light engines, the second component of waveguide eyewear displays.

In addition to diffractive and geometric reflective waveguides, there are other types of waveguide displays. If smart glasses such as the Ray-Ban Meta Display are successful, this could accelerate research and development and drive the emergence of new types and subspecies. Although there are other display approaches such as birdbath optics, waveguides are currently considered the most promising technology for making smart glasses and AR glasses suitable for everyday use a reality.

Sprengard sees the fact that the technology is finally ready for the market and reaching consumers after many years as an important milestone: "This is the beginning of something that will change the way we use consumer electronics in everyday life."

(vbr)