Humanoid robot Figure 02 helps build over 30,000 BMW X3s

The humanoid robot Figure 02 worked continuously at BMW for ten months. Now, Figure AI is drawing an initial conclusion based on key figures.

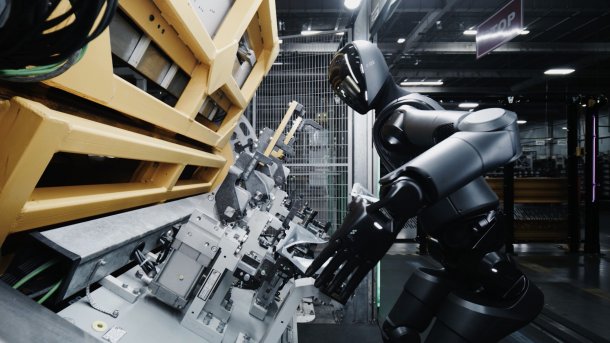

The Figure 02 loads sheet metal parts into a welding machine in BMW production in Spartanburg.

(Image: Figure AI/Screenshot)

The US robotics company Figure AI has drawn a first positive conclusion about the use of its in-house humanoid robot Figure 02 at the BMW plant in Spartanburg, South Carolina. According to the company's statement on Wednesday, the robot was involved in the construction of more than 30,000 BMW X3 mid-size SUVs within ten months. The robot worked daily in a 10-hour shift from Monday to Friday.

At BMW, the Figure 02 was used to remove three different sheet metal parts from shelves or containers and place them into a welding fixture. A six-axis industrial robot then welds the parts together. The component is then further processed. A human normally performs this task. It requires speed and precision. The parts must be placed with a deviation of less than 5 mm within two seconds.

A Matter of Precision and Speed

For a humanoid robot, combining precision and speed is a challenge. This is because the robot must be able to react to deviations in its environment in real-time and adjust its movements accordingly. Figure AI achieved this by using "advanced algorithms for hand-eye coordination." Field calibration tools were also developed to adapt the robot and thus ensure consistent performance.

Figure AI defined various key performance indicators (KPIs) in advance to evaluate the robot's performance. Measured were the cycle time, placement accuracy, and the number of human interventions. Figure AI also defined goals to be achieved. A welding cycle, including loading the parts, should not take longer than 84 seconds, with 37 seconds allocated to loading time. The placement accuracy of the components should be more than 99 percent per shift. Human interventions to correct or maintain the robot should be zero.

Vulnerable Forearm

In more than 1250 operating hours, Figure 02 had only a few hardware failures. However, the robot's compactly built forearm proved to be vulnerable, as it was subjected to significant thermal stress. The forearm houses a microcontroller-based circuit board that regulates communication between the robot's main computer and the wrist actuators. Due to the failures, the communication between the components was redesigned. The main computer then directly controlled the wrist's motor control. This increased reliability and improved thermal management.

Videos by heise

In total, the robots used loaded more than 90,000 parts into the welding machine, performing an estimated 1.2 million robot movements with a total length of more than 320 km. The Figure 02 was involved in the construction of more than 30,000 BMW X3s.

After the tests, the Figure 02 will now be retired and replaced by the new robot generation, Figure 03. The knowledge gained will then be incorporated into the new robot.

(olb)