Study calls for more ecological chip production

The environmental impact of semiconductor production in the EU could exceed that of the steel and chemical industries in a few years' time.

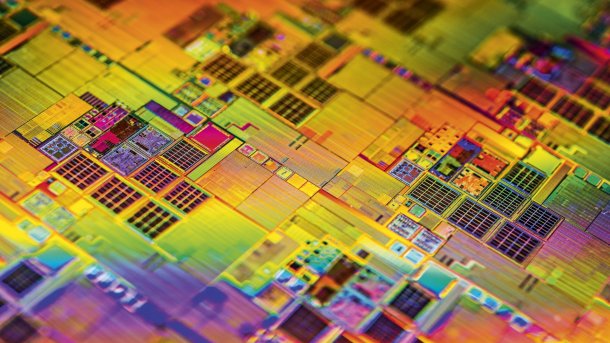

View of a wafer with semiconductor structures.

(Image: c’t Magazin)

Until now, the high environmental impact of the production of semiconductor components has been downplayed: This is the conclusion reached by Julia Christina Hess from Interface. EU politicians who wanted to promote the establishment of more chip production plants with high subsidies have so far ignored aspects such as resource, water and energy consumption as well as the use of problematic chemicals such as PFAS.

However, because the chip industry is growing rapidly worldwide, these problems must now be tackled more consistently.

Videos by heise

Extreme increase

The Interface study "Chip Production's Ecological Footprint: Mapping Climate and Environmental Impact" sees semiconductors as indispensable for the "double transformation" of the coming decades: digitalization and decarbonization. Semiconductors are indispensable for the transition from fossil fuels to renewable energies.

The European Union's declared goal is to increase the EU's share of global chip production from the current 8 to 10 percent to 20 percent by 2030. However, it is not enough to roughly double chip production in the EU, as production capacities are also being greatly expanded worldwide. Expert Julia Christina Hess estimates that, in extreme cases, the environmental impact of European chip fabs will increase eightfold. They would then exceed the impact of today's dominant industries such as steel and chemicals.

Often just plans

Several large chip manufacturers have published plans for climate-neutral production in a few years' time. They also want to conserve other natural resources - in the future. Intel, for example, wants to produce "net water positive" in a few years' time, i.e. provide more clean water than is needed for its own production.

But so far, the reality looks different. According to the documents submitted for approval, the water system of the planned Intel fabs in Magdeburg is designed for 18,600 to 20,300 cubic meters of fresh water per day. At full production, that would be at least 6.8 million cubic meters per year. According to Trinkwasserversorgung Magdeburg (TWM), this corresponds to more than half of the 12.1 million cubic meters required by the entire city of Magdeburg in 2018.

Many chip manufacturers, including Infineon, are also already working on reducing emissions and consumption of perfluorinated and polyfluorinated alkyl substances (PFAS). However, such substances are still being used and are largely removed from the exhaust air using considerable amounts of energy.

Greater efforts needed

The Interface study recommends that concrete measures be taken quickly to significantly reduce the environmental impact of chip production. This will take a very long time, as there are many complex problems to be solved.

(ciw)