Apple prints Apple Watch cases from recycled titanium

Instead of just for prototyping, Apple is now using special 3D printers for the production of Apple Watch cases. The material is recycled.

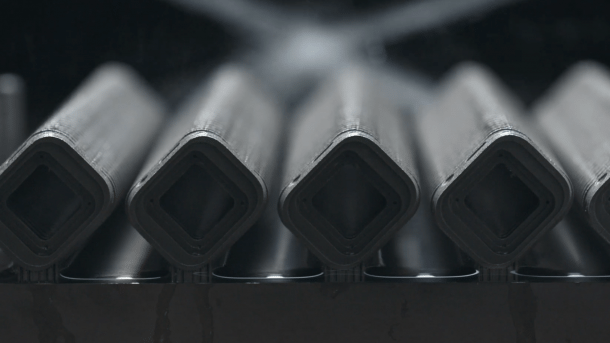

Finished Apple Watch cases from the titanium 3D printer.

(Image: Apple)

Apple has developed a new production process that uses recycled titanium powder to create Apple Watch cases—with the help of a 3D printer. The process was initially “just an idea,” according to Vice President of Product Design Kate Bergeron. The goal was to move from prototyping to mass production. “We had to prove that this technology is capable of meeting our high-quality standards through continuous prototyping, process optimization, and the collection of large amounts of data.”

Six lasers in the galvanometer

Meanwhile, the cases for the Apple Watch Ultra 3 (all models) and the Apple Watch Series 11 (made of titanium) are rolling off the production line. The finish can then be polished as usual. Apple sees 3D printing as an opportunity to increase material efficiency and achieve its self-imposed goal of becoming climate-neutral across the entire supply chain across the entire supply chain more quickly.

Videos by heise

Apple uses an additive 3D printing process where the titanium powder is formed into the desired final shape layer by layer. A total of six lasers are used, which become a galvanometer. This results in 900 layers per watch case. The raw titanium is first processed into the necessary powder form, and Apple must ensure the oxygen content is correctly determined to prevent explosions during processing.

Ultrasonic vibrator recycles the recycled material

The titanium powder is comparable to “very fine sand,” according to Apple. Each layer is 60 micrometers thick. The material that remains is transferred to a collection container using an ultrasonic vibrator for further use. Since the process produces the cases in series, they must be cut afterward—this is done with a thin, electrically conductive wire that requires coolant. 3D printing also has other advantages: it can incorporate textures into the cases much more precisely.

Apple itself operates almost no factories anymore but often buys the necessary machines—or, as in this case, even develops them itself. This has the advantage that the company retains control over their use, and suppliers in China, India, or Vietnam only produce for the company with these machines.

Empfohlener redaktioneller Inhalt

Mit Ihrer Zustimmung wird hier ein externer Preisvergleich (heise Preisvergleich) geladen.

Ich bin damit einverstanden, dass mir externe Inhalte angezeigt werden. Damit können personenbezogene Daten an Drittplattformen (heise Preisvergleich) übermittelt werden. Mehr dazu in unserer Datenschutzerklärung.

(bsc)